Fiber Cleaner Tests

2024-12-08

Intro

This post is a collaboration between Hotaru, error and jo. It is published at swagspace.org as well as undefinedbehavior.de.

The idea behind this post initially came from a talk at DENOG16 about problems with return loss in optical transmission. Our question was: How dirty do fibers get and how much work is it to get them clean again.

Making fibers dirty

We primarily tested two different kinds of contamination. The first kind is touching the fiber. The second kind is contamination with dirt, e.g. from the floor. Both kinds can happen easily when handling fiber.

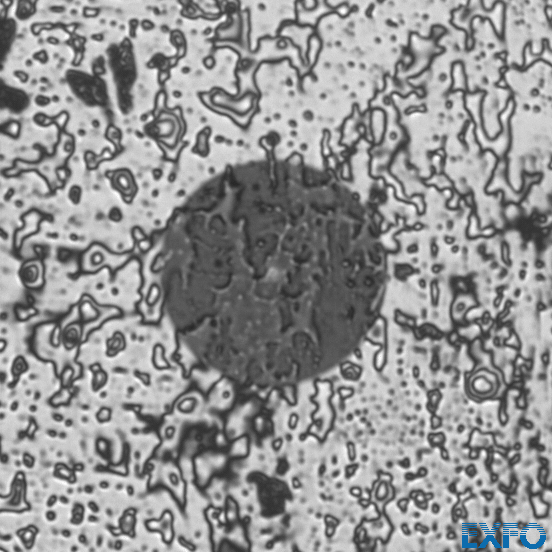

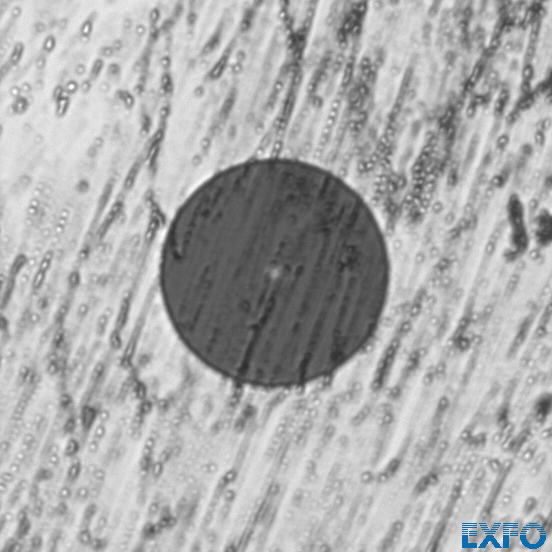

It is interesting to see how visually distinct the different kinds of contamination are. Just touching the polished face of the fiber once with our fingers covered the whole face with a thin grease film.

Swiping over the face of the fiber leads to a more streaky pattern.

The contamination when touching hair is very similar to touching the fiber with your fingers.

Dropping the fiber on the floor (in our case a carpet) contaminates the fiber with many small pieces of dirt.

Different types of cleaners

Click-Cleaners

Click-Cleaners are somewhat pen shaped and fit directly on top of the connector of the fiber. By pushing down on them, a small cleaning thread is dragged over the face of the fiber, cleaning it in the process. Afterwards, a spring pushes the cleaner back into it's original position, ready to be used again.

Manual swiping

Manual swiping cleaners have a button that exposes a piece of cleaning cloth when pressed. The fiber can then be swiped over the cloth to clean it. When the button is released, the cover closes and the microfiber cloth moves forward.

Miscellaneuos "cleaning utensils"

Sometimes you have to improvise. What if you don't have professional cleaning utensils at hand? So we looked at wether a pair of work trousers and a piece of cleaning cloth for glasses work, as well as unicorn Ida and the locomotive Chuff Chuff.

Tests

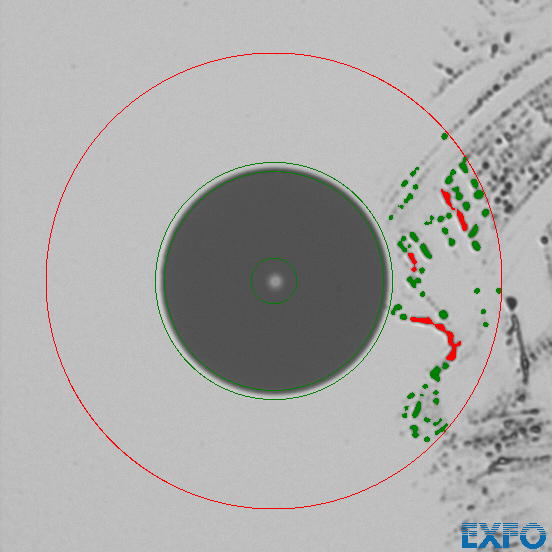

We did several tests with each type of cleaner and different kinds of contamination. We cleaned until the fibers passed IEC 61300-3-35 testing. The standard defines 4 areas of the fiber. The core (A), cladding (B), a small glue area (C) and the contact area of the ferrule (D). The test specification allows for some minor defects on the fiber, especially in the contract area. So there might be some contamination left. Keep this in mind when looking at the figures.

We used an EXFO FIB430B video microscope with automatic analysis features to analyse the fibers.

All our tests were done on Singlemode LC/UPC connectors.

Cletop S

The Cletop S is based on manual swiping. In all 4 tests the Cletop S cleaned the fiber after one swipe.

Senko Smart Cleaner

The Senko Smart Cleaner is of the click cleaner variety. In our tests we had the issue, that this cleaner did not reliably clean the fiber. It looks like some part of the fiber did not get wiped at all.

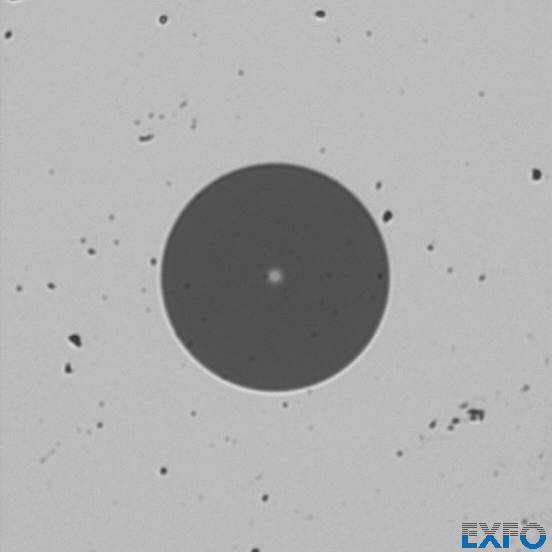

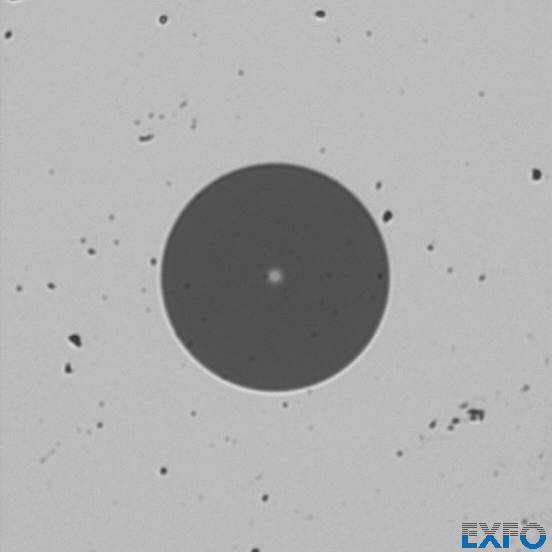

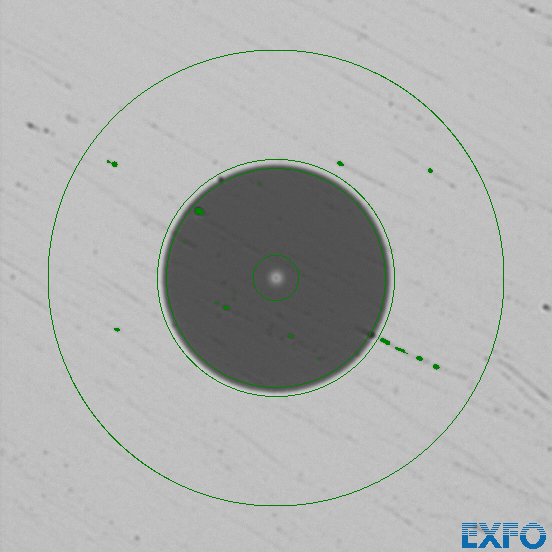

This is an example of a dirty fiber before cleaning

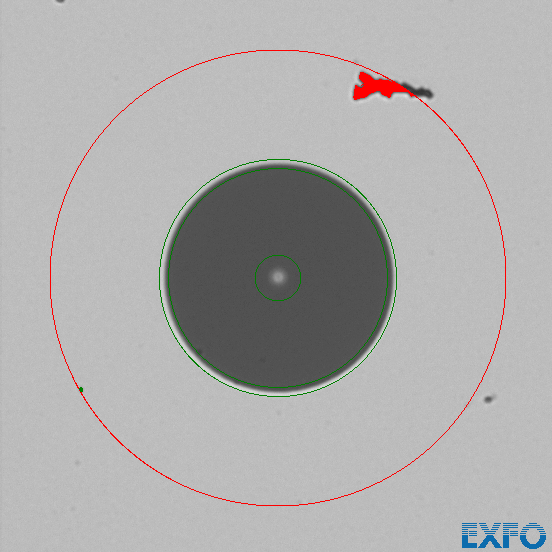

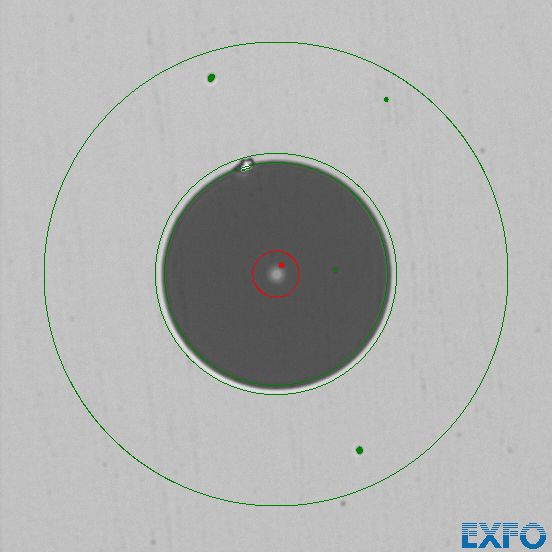

And this is the result of the first cleaning.

We have seen this pattern multiple times with this device during our tests. 3 clicks were necessary in order to reliably clean the fibers.

IBC Brand Cleaner Zi125

This cleaner is also of the click cleaner variety. In all but 1 of our 4 tests this cleaner cleaned the fiber in one click. In the one attempt that didn't clean the fiber, we observed a piece of contamination being moved onto the fiber that wasn't there before.

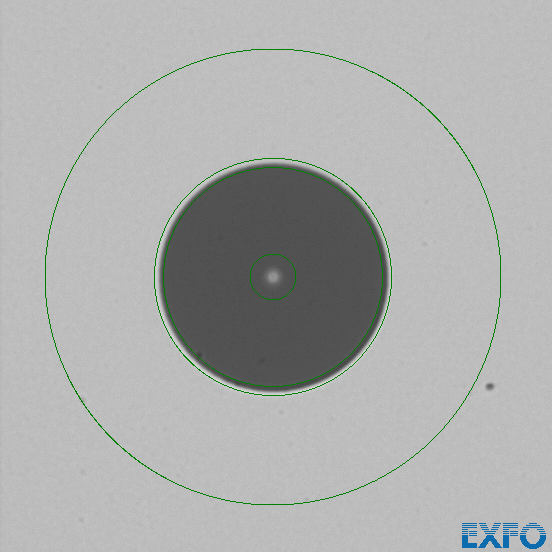

This is the uncleaned fiber. (Note: This fiber passed the IEC test, because the contamination is small enough.) After cleaning this fiber a large piece of contamination was moved into the contact area that was not on our fiber before (or at least not in the part that we were able to observe with out microscope).

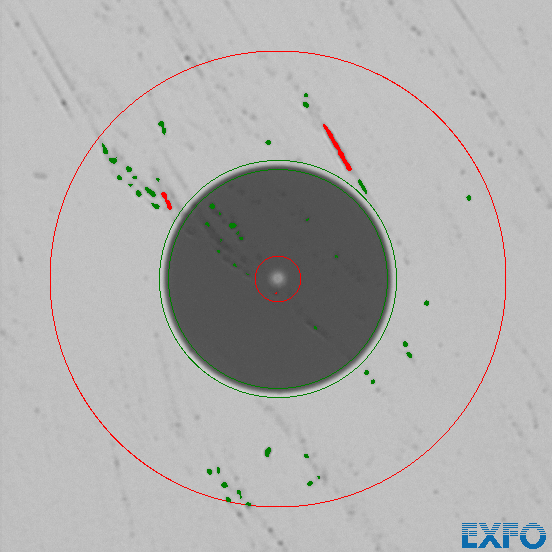

Here we can see a large piece of contamination in the top center. Cleaning it once again removed the defect.

This shows us, that it is possible to introduce new defects through cleaning.

Other cleaning utensils

We had several other "improvised cleaning utensils" at hand so we did a couple of quick tests. Hold on tight, we are entering shitpost territory now.

Work trousers and microfiber cloths for glasses

We did a quick test on a pair of work trousers that were worn for several days. The results were not great.

The trousers were not able to get the fiber clean, not even after several swipes. The other issue with potentially contaminated pieces of clothing is, that you might introduce new contamination.

We tried the same with used microfiber cloth for glasses.

Technically this fiber is clean according to the standard. However there is a significant chance, that the defects still on the fiber end up in the center of the fiber. So we can't recommend this method.

Plushies

In case you are carrying your plushy companion into the datacenter or the field, they might help you cleaning fibers. We did tests with multiple different kinds of surfaces on Chuff-Chuff, a locomotive plushie. Unfortunately none produced good results.

However the results that were produced by unicorn Ida were surprisingly good.

Ida got the fiber almost clean with the first swipe:

There is only one piece of contamination. Sadly that one is directly in the center of the fiber where no contamination is acceptable. Further swipes were not able to remove this contamination. (A purpose-built cleaner did it first try).

Conclusions

- Making fibers dirty is surprisingly easy. Simply dropping them on the ground or touching them is sufficient.

- The Cletop S and IBC Brand Cleaner usually cleaned the fiber in 1 swipe/click, 2 at most.

- If you are not working on very critical optical interfaces 1 swipe on a cletop or 2 clicks from a good cleaner are sufficient.

- It doesn't occur frequently, but it is possible to reintroduce dirt to the contact area of a fiber from other parts through cleaning. If you are working on critical patches, use a scope to verify your work.

- Keep in mind, that this is a limited test on LC-PC/UPC connectors only and that we are only testing the patch cable end of the interface. The results might not hold for other types of connectors like E2k, SC or the APC variants of these connectors.

- Due to missing equipment we were not able to test the cleaning performance of the click cleaners in the recepacle part of the connection, e.g. a transceiver.